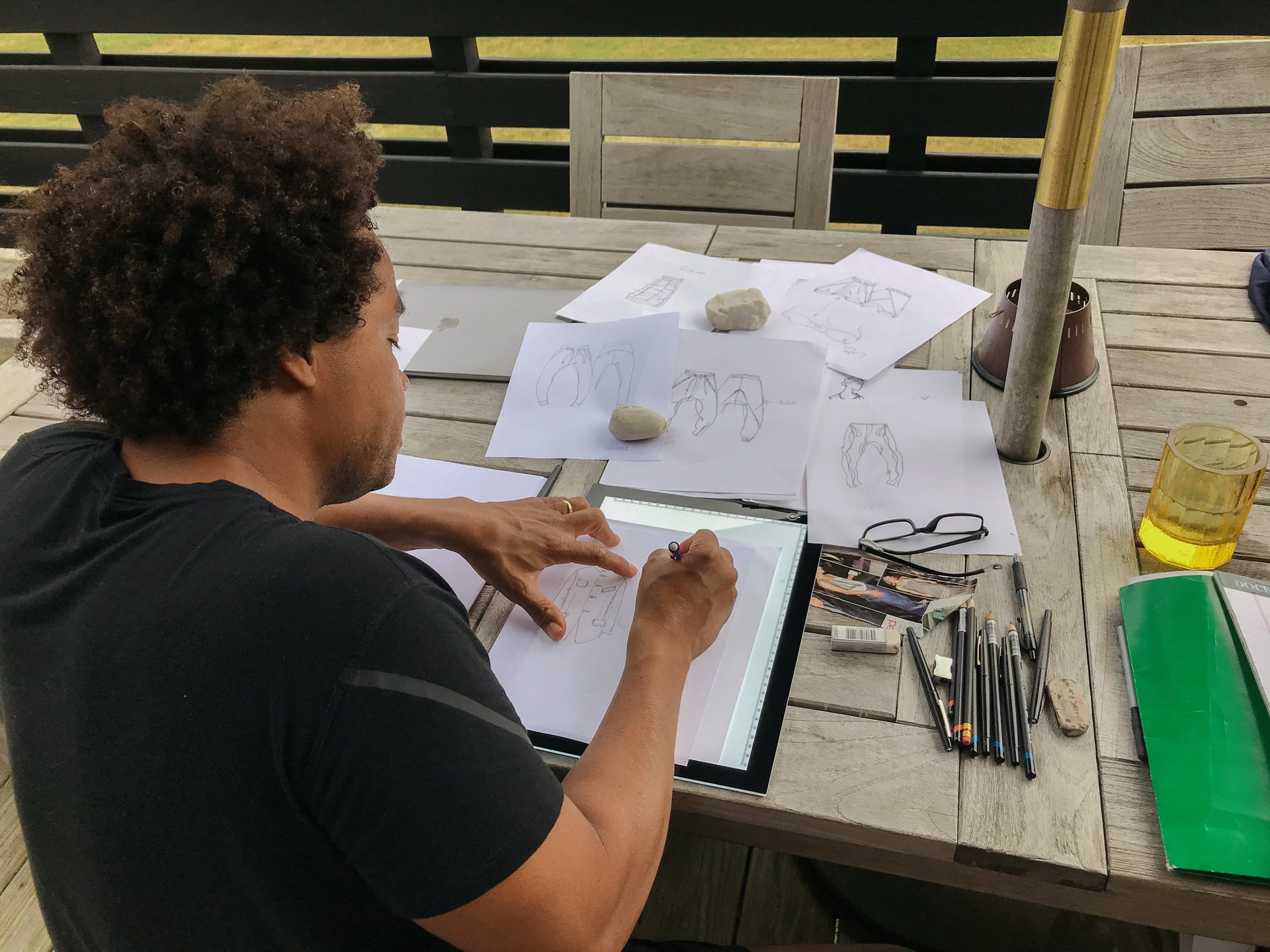

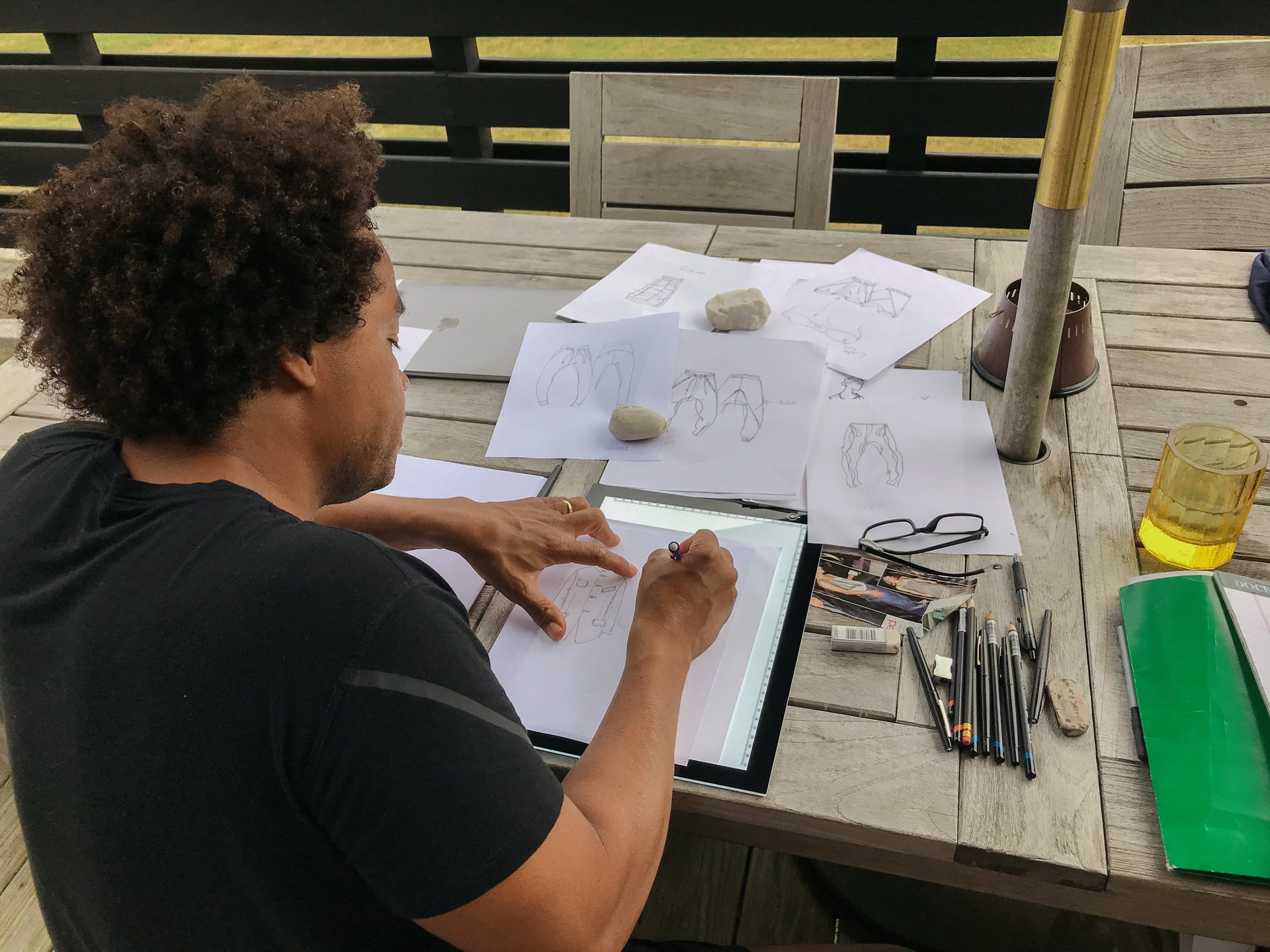

Patrick Robinson & Paskho’s Community-Made Initiative

August 27, 2020

Nicky Campbell

Community Made

Patrick Robinson

PHOTOS COURTESY OF PASKHO

August 27, 2020

Nicky Campbell

Community Made

Patrick Robinson

PHOTOS COURTESY OF PASKHO