Lessons from the Sustainability Bootcamp

April 27, 2016

Laura Toomey

Erin Snow

Erin Snow

K/LLER Collection

K/LLER Collection

Nicholas K

Nicholas K

Prabal Gurung

Prabal Gurung

SVILU

TOME

TOME

WWAKE

WWAKE

Zero + Maria Cornejo

Zero + Maria Cornejo

In early April, Fashion* Initiative Advisory Board Members Dr. Linda Greer (Natural Resources Defense Council), Jason Kibbey (Sustainable Apparel Coalition) and Scott Hahn (Loomstate), as well as Julie Brown (of Sustainable Apparel Coalition) hosted a workshop for the finalists. The Sustainability Bootcamp focused on best practices, environmental “hot spots”, material impacts and supply chain management. The workshop also marked the second phase of the initiative with finalists transitioning from goal setting to defining and focusing on the sustainable actions they will take in their remaining year in the program.

“To really fix the apparel and footwear industry, it requires going far beyond compliance.” Kibbey noted. “We need to dream up solutions that we couldn’t even put in an assessment.” The panelists discussed the changing mentality of the consumers and helped guide the finalists by establishing actionable and immediate steps based on the challenges each is facing.

“Sustainability is a tricky thing for design,” explained Hahn. “It’s an empowering thing to feel confident internally first. Purpose and goals are how you will take sustainability to a new level.”

Here, the finalists reflect on areas of impact, sustainable innovation and next steps based on their takeaways from the workshop.

Erin Isakov, Erin Snow: “How do the clothes we wear impact not only the environment, but also our bodies and wellness? The sustainability bootcamp helped me refine my process for how I can truly accomplish this goal. We are now conducting an audit of our suppliers including trim sources to guarantee that our products are free from harmful substances. The only way to know with 100% certainty is to ask and to be accountable for our entire supply chain.”

Katie deGuzman and Michael Miller, K/LLER Collection: “The Sustainability Bootcamp really made us consider what the end of life is for our products and what we could be doing better. We are analyzing the life cycle for our designs and digging deeper into our manufacturing practices to insure that the companies we work with are compliant with the appropriate environmental and legal requirements. We are inspired by innovative companies who have integrated upcycling programs into their ethos and would like to explore how this concept could work for K/LLER Collection.”

Nicholas and Christopher Kunz, Nicholas K: “Innovation is discovery, whether its novel fabrics, processes, or pioneering ways to incorporate underutilized resources. Developing natural fibers from animals that have a low environmental impact is one great example. Alpaca fiber for instance, is increasingly used in fashion and home goods. Not only does it have great characteristics as a fiber but the Alpaca itself is delicate to its surroundings due to its padded feet, efficient digestion, and eating style. Plus, they are adorable!”

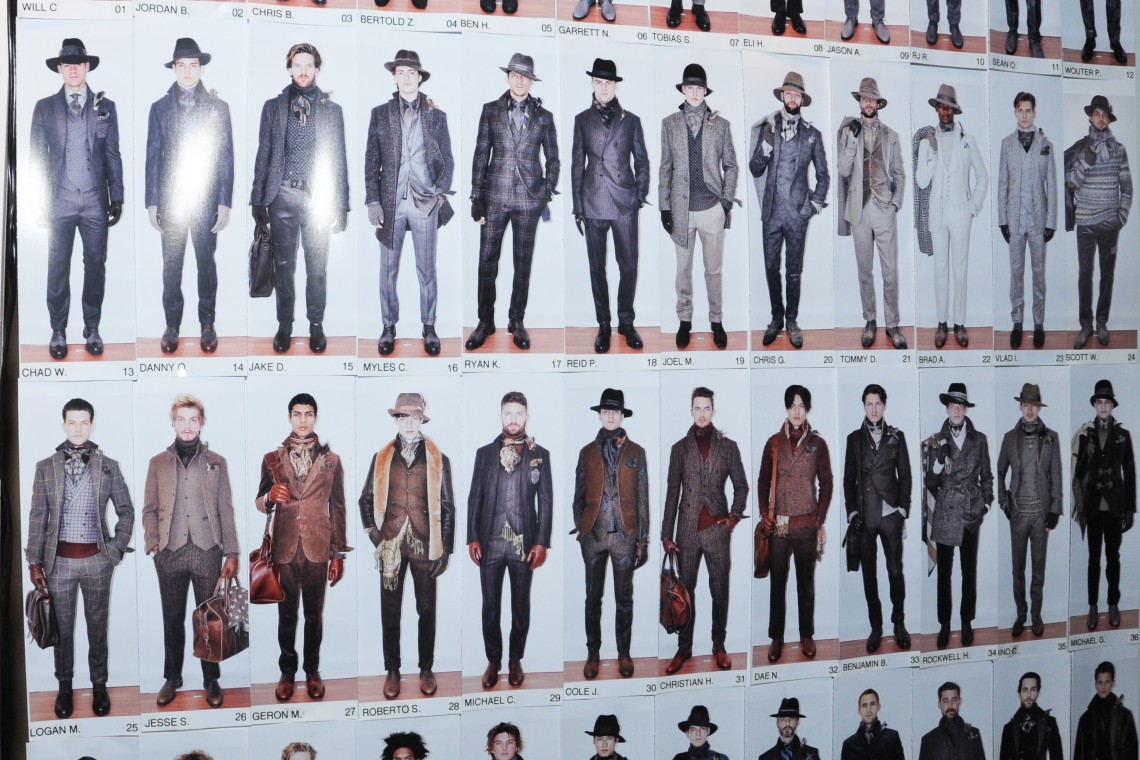

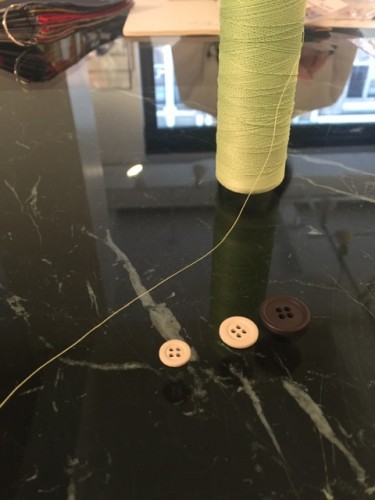

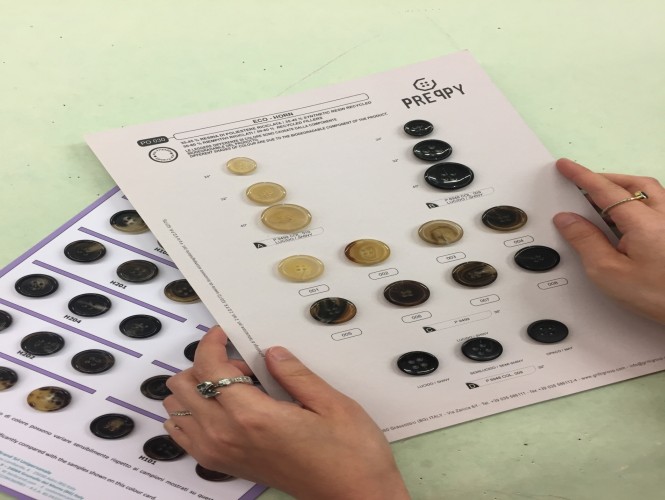

Prabal Gurung: “Annie and Lewis from C2C introduced the PG team to Muller yarns, which are gold certified. We will be exploring the use of these yarns as potential sewing threads to be used in the collection as well as the use of biodegradable buttons in lieu of what is currently used throughout the collection. The PG team met with Saga Furs to discuss best practices and sustainability in fur fashion. Saga talked us through the supply chain and ways in which we can ensure a more traceable approach.”

Britt Cosgrove and Marina Polo, Svilu: “The Sustainability Bootcamp highlighted the importance of considering not just the end materials but to dig deeper and learn more about the process in which our fabrics are being made. We now feel comfortable asking our mills how they track their energy use, monitor their wastewater treatment and prove they comply with local laws. It helped us better understand that there are many ways to achieve sustainability – a cleanly produced synthetic can be a better alternative than a natural fiber.”

Ryan Lobo and Ramon Martin, Tome: “In an effort to reduce our carbon footprint, we are looking to source raw materials closer to home. We have started working with a denim weaver in North Carolina that produces organic cotton denim, combined with tencel and recycled polyester yarns.

On our current trip to Texas and New Mexico, we have connected with artisanal leather manufacturers and looking to source sustainable leather, building on the shearling furs we used for fall 16 collection –completely natural, non-dyed, untreated skins that were a product of meat farming”

Wing Yin Yau, WWAKE: “I started with lessening our environmental impact in the studio: We introduced new ventilation systems into our studio, all-natural soaps, and new equipment that allow us to make work in a more efficient and controlled method. Our studio has additionally decreased waste by introducing a plastic recycling program. Additionally, we have begun purchasing stones and metal not only from traceable sources, but from companies who focus on providing health support and education to small-scale miners.”

Maria Cornejo, Zero + Maria Cornejo: “Innovation, to me, means being creative and original, but also being timeless. This really hit home for me after coming out of the …I loved the idea of getting creative with less. Simplify. Edit. My new mantra.

At the meeting, I realized that we are actually on a great path with core fabric groups such as our silks and alpacas because they are more sustainable than the alternatives according to the list we were given. Seeing that cotton is the worst offender was a real eye-opener.”