Reinventing Fur: Why I Refused to Choose Between Animals and Oil

In 2017, I sold 26 of my own fur coats to start what I thought would be a revolutionary brand: a label determined to be animal-free that would redefine fur for a generation. Like many of my peers, I believed the future was faux.

But when I dug deeper, I realized the “alternatives” weren’t much of an alternative at all. Every faux fur on the market was made of 100% petroleum-based synthetics, mostly polyester. I remember staring at the swatches and thinking I had traded animal cruelty for petrochemicals. From a marketing standpoint, it was uninspiring. From a personal standpoint, it was untenable. How could I advocate sustainability while embracing another form of environmental destruction?

That was the moment I knew I couldn’t build a brand on contradiction. If I wanted to continue, I had to create an entirely new textile.

From Stylist to Scientist (Sort Of)

I came from the creative side of fashion: a former magazine editor, stylist, and creative director. Materials science was foreign territory. But I had the conviction of no animals, no petroleum, no polyester. The fabric had to be compostable or recyclable, scalable on existing machinery, and affordable enough to compete with PET.

The first two years were about persistence and persuasion. I reached out to anyone who might listen, including scientists, textile veterans, and sustainability leaders. Cradle to Cradle and Biofabricate’s founder Suzanne Lee were early champions, reminding me that disruption rarely starts from the center.

By 2019 I had built momentum. David Parkes founder of Concept III textiles, a pioneer in performance textiles, introduced me to Nice Gain, one of the largest faux fur mills. They were experimenting with Sorona, a 38% bio-based fiber from DuPont. For most brands, that might have been good enough. Not for me. I wanted 100%.

The Bioplastics Breakthrough

Then, serendipity: a Dutch polymer innovation company, Senbis Polymer Innovations, followed me on LinkedIn. I reached out immediately. On our first Zoom call, CEO Gerard Nijhoving listened to my “impossible” requirements and didn’t flinch. Instead, he replied: “The answer is bioplastics.”

Bioplastics behave like plastics but are made from renewable biomass such as corn or sugar beets. They contain no petroleum and no polyester. Working with non-GMO corn pellets from NatureWorks, we began the long process of converting pellets into lactic acid, extruding them into yarn, and knitting them into pile textiles.

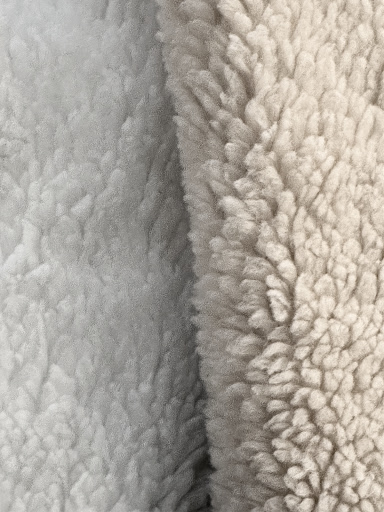

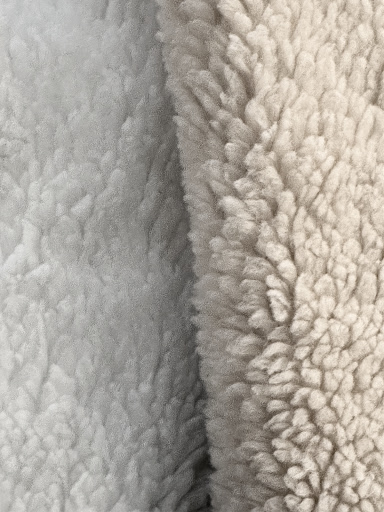

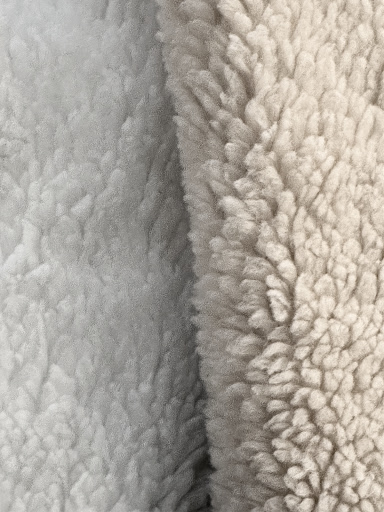

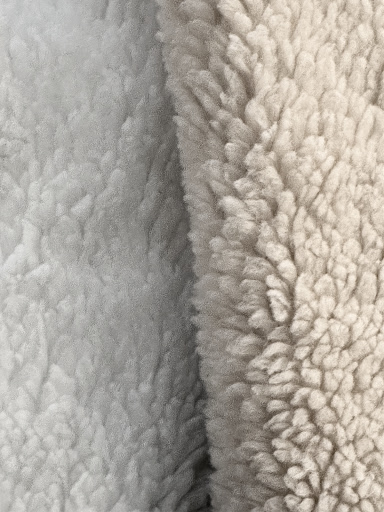

It was a long road—three years of trial, error, and weekly calls with Gerard, David Parkes, Nice Gain, and chief scientist, Mohammadreza Naeimirad. But by early 2025, we had done it. We created BIOFUR® and launched our first textile, BIOsherpa™.