Alan Mak on Version Tomorrow and Material Innovation

May 11, 2022

Sacha Brown

Version Tomorrow x Future World

Version Tomorrow (VT), founded by Public School Managing Partner Alan Mak, is a certified basics and “blanks” platform that enables creators to offer sustainable apparel in an accessible way.

We caught up with Mak to discuss VT’s luxury blanks and basics, collaborations, and roadmap for the future.

How does VT differ from a traditional blanks business like Gildan?

Version Tomorrow is drastically different from a traditional blanks company. Version Tomorrow is the first-of-its-kind luxury blanks and basics platform that attacks the industry from a quality first perspective, all while being eco – whereas Gildan and the like play in the commodity space dominated with low quality garments that don’t feel really luxe and are made with environmentally questionable materials. The Gildans of the world are typically made with conventional cotton blended with various synthetics that shed microplastics throughout their life. At Version Tomorrow, we’ve taken the opposite approach and developed our own RECYCLED+ORGANIC cotton fabrication that is recycled, 100% biodegradable, 100% recyclable and sheds no microplastics. Additionally, our origins are in the fashion world rather than the commodity space – fit matters, style matters, quality matters. When we envisioned Version Tomorrow, the idea was to create a super high quality and luxury product that was more environmentally responsible and where the goods would easily, and do in fact, hang in the world’s best stores.

Additionally, Version Tomorrow is now far more than a blanks program; we’ve grown into a full enablement platform that allows brands and creators of any kind to make more environmentally responsible goods. We’ve taken the complexity and risk out of making eco merch through our full custom platform where we can create fully custom garments utilizing our materials innovation and lower impact supply chain. This includes milling new fabrications to our client’s specs, creating fits that mirror their existing goods, and even creating totally new fits and silhouettes.

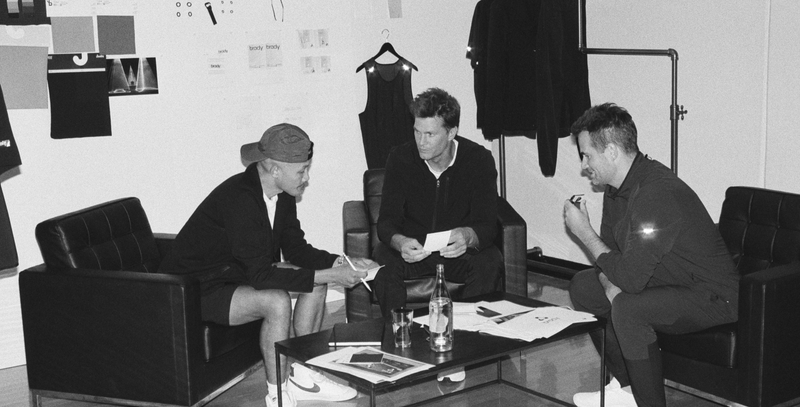

How is VT collaborating with Tom Brady on BradyBrand?

Similar to our other clients, we’ve made it super easy for Brady Brand to make eco product. When we first started talking, the goal was simple – to help them make environmentally responsible product that is elevated and didn’t involve any compromises in quality. The styles that we produce for them have different technical elements in the construction that set their products apart from others. These details require more care, consideration and expertise in the manufacturing process that make the production process a bit slower, but ultimately worth it because their designs reflect a different and greater level of thought.

With the tremendous visibility that Tom Brady can bring to the production of this merchandise, is it important when collaborating with brands that the mission/values of VT be communicated to the consumer?

We are reaching a point where the values of Version Tomorrow are must-haves for brands. Sophisticated consumers are demanding better product – better in quality and better for the environment. What we are doing isn’t a passing fad; care for the environment, care for workers, etc – these themes aren’t going away. It’s our hope that we can be a strong voice that raises even greater awareness and accelerates change. By showing that we can make more environmentally responsible garments using recycled materials that are uncompromised in quality, brands and consumers no longer have to make a choice when they are buying. The days where being eco and of amazing quality are mutually exclusive are gone when brands join us. We’re here for what’s next…eco without compromises.

But to answer your question more directly, YES, we love when our customers share our values and story tell alongside us. We recently collaborated with a super cool makeup brand (we can’t tell you who yet) on a capsule that’ll be launching soon. We’re really excited and honored that they are including Version Tomorrow’s story along with every one of the pieces. Our customers who story tell alongside us are also doing their part to push the movement forward – they too are change accelerants, not just through their choices in terms of production, but also via their voices. They are extensions of our ethos and are megaphones for our mission.

Do consumers value this level of transparency?

More and more, customers are telling us that they care…and for those that don’t, hope is not lost since we’ve done the work anyway! Everyday, I have conversations with customers who almost always ask about our materials and what our supply chain looks like. When Version Tomorrow was envisioned, part of the goal was to not only create a more environmentally responsible product, but to also prove it and have that proof be a part of the value proposition we offer our clients. Version Tomorrow has obtained and is backed by multiple certifications that cover our fabrication (our recycled content is GRS certified and our organic content is OCS and/or GOTS certified), our eco-friendly and non-toxic dyes (Oeko-Tex Standard 100 certified) and we also have third party audits for our labor.

Targets have been set to reduce greenhouse-gas emissions to net 0 by 2050, does VT have a roadmap to reducing its carbon footprint?

From the beginning, the goal was to produce the highest quality goods with the lowest possible footprint. Unlike other companies that have historically operated with dirty and carbon intensive supply chains, which have lots of room for reduction, we had the luxury of creating a totally new lower impact product and supply chain from the start. Additionally, our product was designed with circularity in mind, so not only did we seek to create a lower impact product and supply chain, but we also planned for our products’ end of life.

This all starts with our fabrication where our unique recycled+organic cotton blend has a lower footprint and tremendous water savings over conventional cotton without compromising softness and quality. Our supply chain includes factories that operate using renewable energy sources such as solar and hydroelectric power, we use dyes that are Oeko-Tex Standard 100 certified for non-toxicity, and after dyeing, our water is purified and regenerated for future use. Another initiative that I’m super excited and proud of, is that we recently announced that alongside esteemed companies such as Nike, J. Crew, Stella McCartney, Noah, and Herman Miller, Version Tomorrow will be an early adopter of solutions that come out of the Tom Ford Plastic Innovation Prize to test and utilize products to eliminate thin film plastic (aka plastic poly bags) from our supply chain. We’re thrilled that we were able to partner with Lonely Whale and were invited to be a part of this cohort.

Further, since Version Tomorrow is circular by design, to tackle end of life, we’ve partnered with a number of organizations and companies to create take back programs that don’t simply resort to the more carbon intensive process of immediately racing to recycle garments. Rather, we’ll be stratifying our stream in a far more thoughtful manner where we believe that end of life streams should be split and stratified into reuse, mend and repair, upcycle, recycle and downcycle. Many brands within our industry look at recycling as the holy grail and the first step; it’s not and it shouldn’t be. Recycling textiles is more carbon intensive and potentially unnecessary when there are other options that are less carbon intensive and can keep existing garments in circulation or yield a new life to garments which have reached “end of life”. However, if our garments can’t find a second life or stay in circulation, since Version Tomorrow’s fabric is a monofiber (of a single fiber type), it can easily be recycled into new cotton fabric using existing mechanical means that do not require new and unproven technologies that can’t yet scale…and if that isn’t an option, our garments will biodegrade and will not pollute harmful substances as they breakdown.

All this said, we aren’t perfect and are still constantly looking at ways to innovate and become even better.