American Design Excellence From 2024 FMI Grant Fund Factories

November 27, 2024

Aldo Araujo

On Monday, the Fashion Manufacturing Initiative (FMI) announced this year’s recipients of the FMI Grant Fund. In it’s 11th anniversary, the CFDA and the New York City Economic Development Corporation distributed over $1.1 million to 18 domestic manufacturing facilities committed to improving their services through innovation and technology.

We spoke to to three factories grantees—Dream Fashion, Glory Apparel and theTEN Atelier—and designers they work with to showcase the strength of Made in NYC, and why America’s domestic manufacturing industry is strong, displays excellence in craft, and is worth celebrating.

Click her for our full open access Production Directory on CFDA.com, featuring 380 local U.S. manufacturing resources for designers looking for new development and production partners.

Linda Eun of Dream Fashion with model Dominique Castelano in Bibhu Mohapatra.

Model Dominique Castelano wearing Bibhu Mohapatra at Dream Fashion.

Linda Eun of Dream Fashion with model Dominique Castelano in Bibhu Mohapatra.

Model Dominique Castelano wearing Bibhu Mohapatra at Dream Fashion.

Model Dominique Castelano wearing Bibhu Mohapatra at Dream Fashion.

Model Dominique Castelano wearing Bibhu Mohapatra at Dream Fashion.

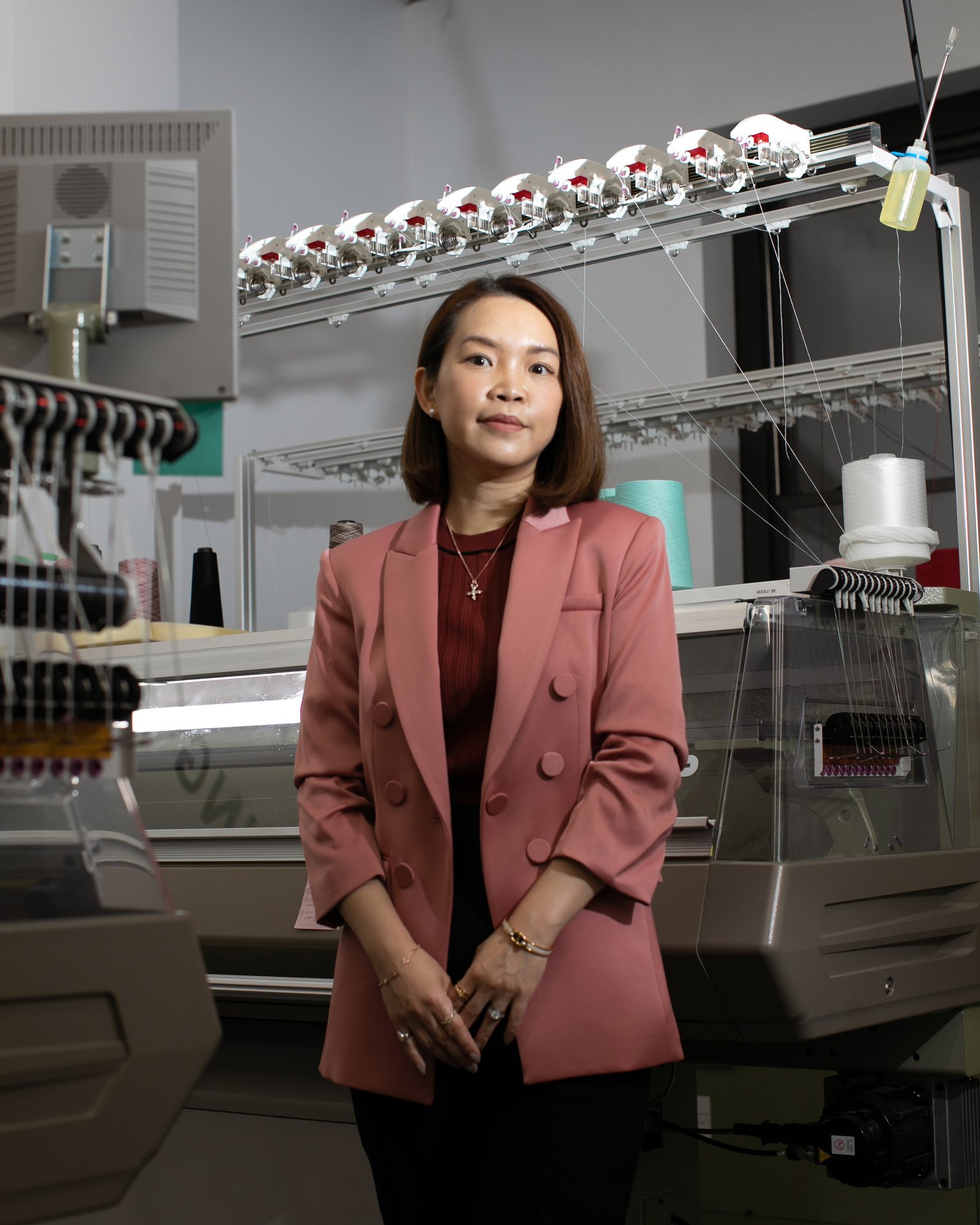

Linda Eun of Dream Fashion

Tell us about your factory and business.

I run a domestic factory. I live my life with pride. I will spend my life making clothes. Good quality and on-time delivery is how I operate.

What does being a recipient of the 2024 FMI Grant Fund mean to you and your business?

Being a 2024 FMI Grant Fund recipient will really help me a lot in learning the business.

Dominique Castelano wearing Agbobly at Glory Apparel.

Dominique Castelano wearing Agbobly at Glory Apparel.

Dominique Castelano wearing Agbobly at Glory Apparel.

Dominique Castelano wearing Agbobly at Glory Apparel.

Dominique Castelano wearing Agbobly at Glory Apparel.

Karen Au of Glory Apparel.

Karen Au of Glory Apparel

Tell us about your factory and business.

Glory Apparel is a one-stop shop solution for all of your knitwear needs. We provide everything from yarn sourcing, stitch development, sampling and on-demand production. Our production minimums are very low at 6 pieces per style, and we work with each client to meet their expectations for their specific needs and goals within the time frame given.

Discuss the finished garment and factory technology behind the look.

The garments made for Agbobly were knitted using our Shima Seiki flat bed machines. The entire production process was done in house – from knitting of the panels, washing, linking of the garments, pressing, labeling and final packaging.

ApexFIZ was also used. It is a Shima Seiki’s design software that gives us 3D renderings of our knitted garments, which allows us to preview how each design would actually look in real knitting format, hence minimizing knitting errors and reducing yarn wastage going into production.

What does being a recipient of the 2024 FMI Grant Fund mean to you and your business?

This is our second time and consecutive year to receive the FMI Grant Fund. We are extremely humbled and grateful for the opportunity and support given to us by the CFDA. With this year’s grant, we were able to purchase two new Shima Seiki knitting machines, and one of them is the latest WholeGarment model, which is considered to be the best in terms of advanced technology in the industry right now for seamless knitting.

We are excited to offer new products and services to our clients with the help of this latest technology as well as the knitting expertise provided by our professionally-trained staff. We welcome anyone who is enthusiastic about knitwear and would love to collaborate with those who have a specific sweater vision in mind!

Dominique Castelano wearing Kate Barton at theTEN Atelier.

Dominique Castelano wearing Kate Barton at theTEN Atelier.

Angelique Julien of tenTEN Atelier with model Dominique Castelano in Kate Barton.

Dominique Castelano wearing Kate Barton at theTEN Atelier.

Dominique Castelano wearing Kate Barton at theTEN Atelier.

Dominique Castelano wearing Kate Barton at theTEN Atelier.

Angelique Julien of theTEN Apparel.

Angelique Julien of theTEN Atelier

Tell us about your factory and business.

I started theTEN atelier rather organically. In 2014, I founded my company after the collapse of Rana Plaza in Bangladesh. The wastefulness of fast fashion along with the human and environmental impact really moved me to build a company where we could do things the right way: more thoughtfully, with respect to our planet and the people whose hands bring the garments to life, from the farmer, to the mills, and factory workers.

The process of building a complete pattern entirely by hand is incredibly time consuming from sketch to realized runway sample and then production fit. It can often take 3-4 samples before it’s sales ready.

What does being a recipient of the 2024 FMI Grant Fund mean to you and your business?

Being a recipient of the CFDA FMI Grant Fund is transformative. With the grant we’ve invested in Lectra technology along with Alvanon physical and digital forms, which are American standard sized, scanned from real bodies. We can test fit and pattern viability on avatars, which allows us to get to production fit much faster, which also cuts down the amount of physical samples needed for testing.

We still believe in doing things the right way: with respect to the time tested skills of draping and beautiful construction, but the intertwining of technology helps us bridge the time and cost barriers and use less physical materials.

PHOTOGRAPHY BY ALEX JUSTIMBASTE (@THEDIVASORIA)